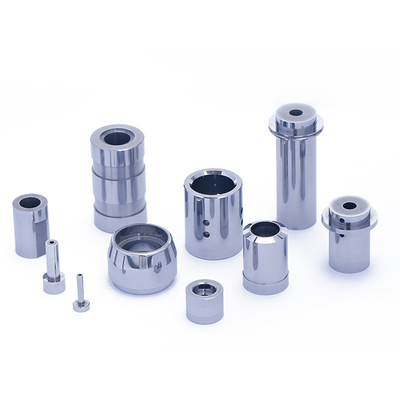

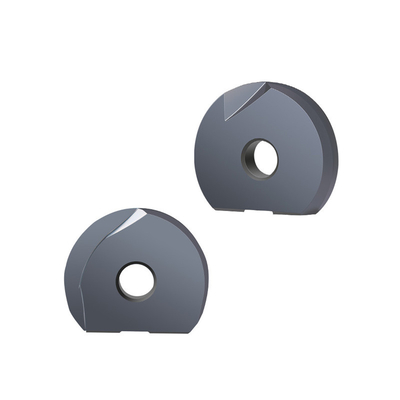

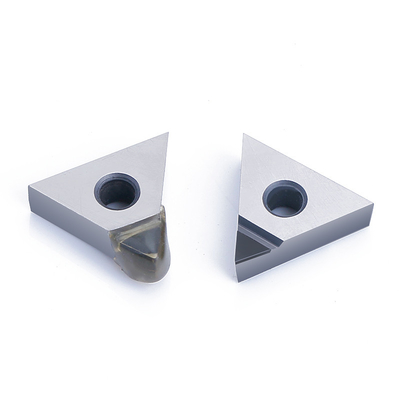

Wolframkarbid-Stanzformkomponenten für Schmieden, Befestigen, Federn

Produktbeschreibung

Wolframkarbid-Formen für Schmieden, Befestigen, Federn, Lager, Ziehen, Walzen usw.

Anwendungsbereich

Wolframkarbid wird häufig in Formen und Werkzeugen verwendet. Klassifizierung wie folgt:

| Klassifizierung |

Anwendung |

| Schmiedegesenk |

Schmiedeformen für Automobilkomponenten, die durch Warm-, Kalt- und Präzisionsschmiedeverfahren hergestellt werden |

| Befestigungsgesenk |

Befestigungsprodukte für die Automobil-, Bau-, Haushaltsgeräte-, Luft- und Raumfahrtindustrie und andere Industrien |

| Federwerkzeug |

Werkzeug für Präzisionsfedern, das in Automobil- und High-End-Elektronikprodukten verwendet wird |

| Lagerwerkzeug |

Werkzeug zur Herstellung von Lagerprodukten, einschließlich der Formgebung von Kugellagern, Radlagern und Ringen |

| Pulvermetallurgie-Form |

Verschiedene Präzisionszahnradteile für Automobil-, Motorrad- und Elektronikprodukte |

| Walze |

Verschiedene Walzenprodukte für die Drahtformung und den vorderen Teil der Produktion |

| Zieheisen |

Werkzeuge, die bei der Durchmesserreduzierung und -formung von Draht und Rohr verwendet werden |

| Optische Form |

Hochpräzisionsform für die Photovoltaikindustrie, die bei der Verarbeitung von asphärischen Glaslinsen für Mobiltelefone, Kameras und Sicherheitsüberwachung eingesetzt wird |

| Dosenherstellung |

Werkzeuge für die nahtlose Zinnformung, bieten Lösungen für das Stanzen, Strecken und Zurückziehen |

Produktdetails - Hartmetall-Zieheisen

- Oberflächenrauheit: RZ~~0,2 µm / F1,0 mm/min

- Genauigkeit: ±0,001 mm

- Anpassung: Absolut kundenspezifisch. Für diese Produktserie gibt es keinen Standardbestand, und es werden nur Sonderbestellungen akzeptiert. Bitte fügen Sie Ihrer Anfrage CAD-Zeichnungen/3D-Zeichnungen bei.

Material

Reines Wolframkarbid mit Co-Elementen, Eigenschaften wie folgt:

| Material |

Materialeigenschaften |

| Hartmetall: |

Hartmetall ist ein pulvermetallurgischer Verbundwerkstoff, der aus einer oder mehreren Hartstoffphasen (z. B. Wolframkarbid) und einem Bindemittel (z. B. Kobalt) besteht. Es ist ein extrem hartes Material, das sich durch hohe Verschleißfestigkeit und thermische Stabilität auszeichnet. Es wird in verschiedenen Bereichen eingesetzt, in denen Werkzeuge oder Komponenten besonders verschleißfest sein müssen. Im Vergleich zu Werkzeugstahl ist es schwieriger zu bearbeiten und hat höhere Materialkosten, aber seine Lebensdauer ist oft um ein Vielfaches länger als die von Werkzeugstahl. |

Eingesetzte Bearbeitungstechnologie

Eingesetzte Produktionstechnologie: Rundschleifen, Innenschleifen, optisches Profilschleifen, Flachschleifen, Gewindebearbeitung, Mittelschnitt-Drahtschneiden, Langsamschnitt-Drahtschneiden, Funkenerosion und so weiter.

Warum uns wählen

- Fortschrittliche Technologie:Komplexe Formen und verschiedene Strukturen können schnell geformt und präzise gehalten werden.

- Effiziente Verarbeitung:Kurzer Produktionszyklus und schnelle Lieferung, um den Versandplan gemäß dem Liefertermin sicherzustellen.

- Produktqualität:Gleichbleibende Qualität garantiert. Hohe Genauigkeit, bis zu ±0,003 mm.

- Vertraulichkeitssystem:Dreifache Vertraulichkeitsmaßnahmen zum Schutz. Bei Bedarf können wir eine NDA (Non-Disclosure Agreement) unterzeichnen, was die Prüfung sicherer macht.

- High-End und voll ausgestattet:Hervorragende Verarbeitungskapazität, mehrere Produktionslinien, fortschrittliche Ausrüstung, professionelle unterstützende Einrichtungen.

- Kostengünstig:Angemessene Konstruktion und Materialauswahl führen zu einem wettbewerbsfähigen Preis, so dass wir Ihnen einen günstigeren Preis für Produkte des gleichen Niveaus anbieten können.

Kinyet konzentriert sich die ganze Zeit auf die Forschung und Entwicklung von Wolfram-relevantem Material. Durch die ständige Einführung neuer Technologien und die Erhöhung der Investitionen in High-End-Produktionsanlagen ist Kinyet in der Lage, Formenlösungen mit einem hohen Preis-Leistungs-Verhältnis anzubieten, einschließlich hoher Präzision, längerer Werkzeuglebensdauer und Wirtschaftlichkeit usw. Jetzt ist Kinyet mit Drow fusioniert. Mit dieser leistungsstarken Kombination werden wir in Zukunft noch bessere Produkte für den Verbraucher schaffen!

Qualitätskriterien

- Verschleißfestigkeit

- Präzision

- Korrosionsbeständigkeit

- Schlagfestigkeit

- Zähigkeit

- Elastizitätsmodul, Steifigkeit

- Querzugfestigkeit. Usw.

FAQ

F1: Produzieren Sie spezielle Stanzformen oder Stanzformkomponenten?

A: Ja, wir sind auf die kundenspezifische Formherstellung spezialisiert und setzen die komplexesten Stanzformideen in die Realität um. Die von uns hergestellten Stanzformkomponenten werden für verschiedene anspruchsvolle Anwendungen und eine Vielzahl von Materialien entwickelt und angepasst!

F2: Akzeptieren Sie geringe Mengen für Musterbestellungen? Und was ist Ihr MOQ für die Anpassung?

A: Ja, das tun wir. Für Musterbestellungen wird ein MOQ von einem Stück akzeptiert. Bitte fügen Sie Ihrer Anfrage CAD-Zeichnungen/3D-Zeichnungen bei, und die Musterlieferzeit beträgt 10 bis 15 Tage. Für andere spezielle Anforderungen kann verhandelt werden.

F3: Wenn wir mit Ihnen zusammenarbeiten möchten, ist es dann möglich, Vertraulichkeit zu erhalten?

A: Sicher, alle Ihre Informationen, einschließlich Firmeninformationen, Zeichnungen, Bestellungsdetails, werden vertraulich behandelt, wir können eine NDA unterzeichnen, wenn Sie dies wünschen (Non-Disclosure Agreement).

F4: Wie lauten Ihre Zahlungsbedingungen?

A: T/T 30% als Anzahlung und 70% Restbetrag vor Auslieferung. Wir zeigen Ihnen die Fotos der Produkte und Verpackungen, bevor Sie den Restbetrag bezahlen.

F5: Was können Sie von uns kaufen?

A: Hartmetalleinsatz, Hartmetall-Schaftfräser, Hartmetallbohrer, Hartmetallbohren, Schneidwerkzeuge & kundenspezifische Hartmetall-Präzisionsformen.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!